Technology

Kansai International Airport, Japan

Published

7 months agoon

Kansai International Airport, Japan; An artificial terminal on the sea

Osaka Kansai Airport is built on an artificial island in Osaka Bay. This airport was opened in 1994 and its development operation was completed in 2007. It goes without saying that the construction of this airport was by no means an easy task; Although the Japanese are known to do difficult and regular engineering projects in the world. Two mountains were completely razed to the ground for the construction of the island, and according to the Civil Engineering Institute, this airport became the most expensive construction project in the world at the time of its completion.

Despite the amazing engineering achievements such as withstanding earthquakes and strong storms that have been proven by the construction of this structure, in recent years structural problems have emerged in this island airport, most importantly the island is settling at a faster rate than originally predicted, and this has led to It has led to problems such as frequent flooding.

In this article, we will go into details about the background of the airport, construction operations, operation, and of course the future plans of the Japanese government for its development. By reading this article, you can learn about one of the most admirable civil engineering projects in human history, and of course, one of the most amazing airports in the world.

The initial idea for the construction of the airport

Need to build an airport in Osaka

In the 1960s and 1970s, several important events led to the construction of the airport. The first case was the decrease in the share of Osaka and Kobe in the trade market and the prosperity of business in Tokyo. The proposal to build Tokyo’s second airport called Narita was proposed in 1966 and its construction was completed in 1978. Many exporters had to use Tokyo airports instead of local airports to send their goods abroad.

The second case was the low capacity of Osaka’s first airport, Itami. Itami Airport is located in one of the densely populated suburbs of the Osaka metropolitan area. This airport was opened in 1939 and was first used by the Japanese army; But after World War II, the United States Army also used this airport. Since 1959, Itami Airport has been used for civilian purposes, and by carrying out development projects, it became one of the central hubs of international airlines in a short period of time.

Japan’s aviation industry experienced unprecedented growth within 20 to 30 years and since the 60s, the capacity of the Osaka airport alone did not meet the high volume of demand. Due to the location of Itami in the center of a densely populated area, there was no more space for the development of the airport. On the other hand, the noise pollution of the airport and the protests of residents of residential areas caused more problems for the only airport in Osaka. In the 1970s, Itami Airport reached its maximum capacity, and the officials concluded that Osaka needed a new airport.

Choosing a place to build

The construction of the artificial island was not the first option of the airport designers. In the initial plan, it was proposed to build an airport near the port city of Kobe. The construction of the airport in this place could be useful for both cities due to the existence of extensive communication infrastructure. In addition, Kobe did not have an airport. However, the city of Kobe opposed the construction of the airport in this place and the designers had to look for another place to build their airport.

Having learned from the problems encountered for Itami Airport, the designers were looking for a location far from urban areas. In this case, the construction site could advance the construction operation 24 hours a day. Also, the problems encountered in the design of Narita Airport in Tokyo were also one of the main influencing factors in choosing the location of the new Osaka Airport.

In the 1960s, public protests intensified by Osaka residents and landowners, who claimed that they were not consulted during the airport’s design process. On the other hand, the left-wing parties opposed the construction of this airport due to the concern about the expansion of the capitalist system in Japan and greater alliance with the United States of America

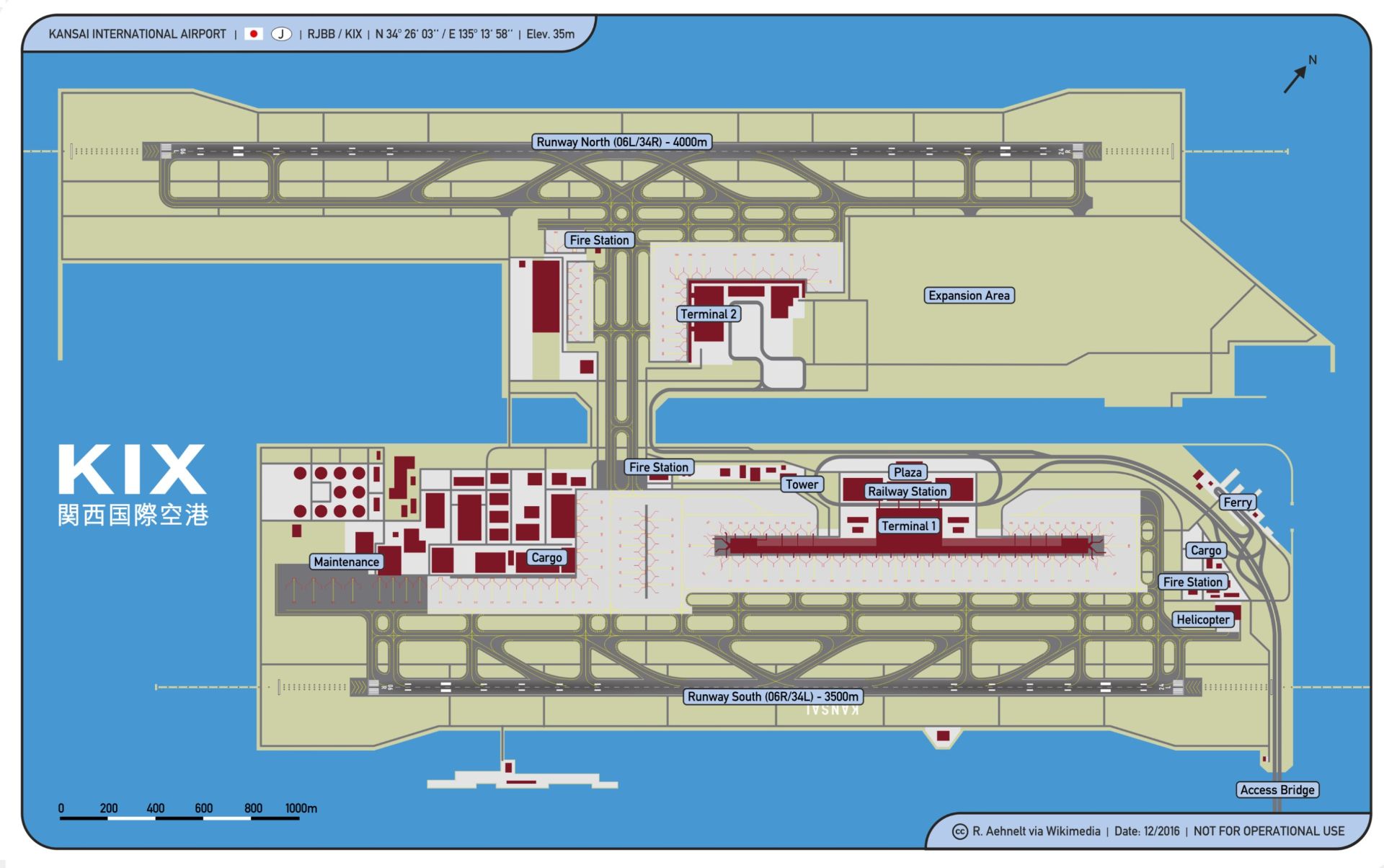

The Ministry of Transport of Japan, after reviewing six proposals for the construction of an airport in the sea, decided to build an artificial airport island in Osaka Bay south of the city. In the proposed plan, the island was 4 kilometers long and 2.5 kilometers wide, and it was built at a distance of 5 kilometers from the coast.

The construction of the airport required advanced and complex engineering; Because this airport had to be resistant to earthquakes, storms, and floods. After the approval of the proposed design, the construction of the island started in 1987.

Kanzai International Airport

History of construction of artificial islands in Japan

The idea of building such a large island in a relatively deep bay (the water depth in Osaka Bay reaches 18 meters and its bed is made of soft clay to a depth of 30 meters) may seem ambitious. But Japan has a long history of building artificial land in water or so-called land reclamation; Because land is expensive and scarce in many areas of Japan.

The history of artificial land construction in Osaka Bay dates back to the Edo period (1600-1867 AD) when the land built in the sea was used to plant rice in the coastal plains. However the construction of artificial ground in Japan accelerated after the end of World War II; Because of the rapid increase in Japan’s economic growth, there was a great demand for new land. According to the statistics of the Japan Real Estate Center Construction Company, 0.5% of the land area of Japan is artificial and reclaimed in the sea.

The construction stages of the airport and its infrastructure

Land stabilization

The construction of the airport started in 1987. First of all, the airport land had to be built inside the seawater. The construction of the artificial island took three years, and in order to obtain the required materials, two mountains located near the site of the airport were completely razed to the ground. The airport is actually built on two islands, each of which has a runway and a terminal. Although the construction of the entire airport structure started in 1987; But the first priority of the contractors was to complete Island No. 1, which was completed in 1994. The completion of the construction of the second island took until 2007. The first island with an area of 511 hectares is slightly smaller than the second island with 535 hectares.

The main challenge in building the islands was not the depth of the water but the conditions of the sea bed. The bed of Okasa Bay consists of soft clay, which is also called alluvial clay, and 70% of it is water.

To solve this problem, engineers used the sand drying method. In this method, deep tubes are lowered into the seabed, tubes filled with dry sand. When the pipes are removed from the seabed, the sand columns left behind absorb water from the clay and reduce its ability to shrink. By adding more weight of sand, more clay moisture is absorbed into the sand columns. 2 million sand columns were used to stabilize the Kanzai airport bed.

Despite the measures taken in the field of stabilization and strengthening of the seabed, the island and the airport built on it have settled over time. The creators of the project consulted with several experts to solve this issue, and finally, some estimates were prepared about the amount of airport settlement. According to reports from the University of California, San Jose, the estimates provided by the experts had predicted ground subsidence between 6 and 8 meters after the construction of the airport, so the engineers took the most pessimistic estimate and proceeded with the construction of the project, but as it turned out later, this strategy basically failed. It was wrong.

Kansai International Airport

Great land reclamation and island construction operations

After stabilizing the land, the next step was to build a sea wall and fill the reclaimed land. Around the construction site of the island, 69 large metal enclosures were built, and then the space between these enclosures was filled with 48,000 tetrapods. A Tetrapod is a special concrete structure designed to protect structures against waves and surges by dispersing the force of advancing water.

In the next step, the central space of the island was filled with stones. For this work, 430 million cubic meters of stone were used. This amount of stone was extracted from three nearby mountains at a distance of 10 to 30 kilometers from the airport construction site. One of the important points in the construction of the island was its final height. This height should have been calculated based on the estimates of the amount of sedimentation of the clay layer of the seabed. Of course, the subsidence of the bed layer would stop after some time, but the final amount of ground subsidence was not known to anyone.

According to the reports of Geotechnics and Geoenvironment magazine, the final height selected for the first island was 36.7 meters from the seabed, and for the second island, it was 40 to 43 meters.

Start of construction of the airport

The construction work of the airport and terminal facilities of the first island began in 1991 and after the completion of the revitalization of the first island. It should be mentioned that in the first stage, the goal was to build only one runway and one terminal. An Italian architect named Renzo Piano was commissioned to design the main building of Terminal 1. Piano had previously designed the Georges Pompidou National Center for Arts and Culture in Paris. Among his other works, we can mention the Potsdamer Platz square in Berlin and the pyramid-shaped Shard tower in London.

Terminal 1 of Kansai Airport is 1.7 kilometers long, and in this respect, it is called the longest terminal in the world. However, some of the world’s major airport terminals are higher than Kansai Terminal 1 in terms of total area, including the largest terminal in the world, Daxing Airport Terminal. pointed out in the city of Beijing. In the early stages of the construction of the airport structure, the Japanese government intended to shorten the length of the terminal to save costs; But Renzo Piano insisted on building the terminal based on the original plans.

The structural load of the terminal is supported by height-adjustable columns. The design of these columns is such that they compensate for the change in height caused by the settlement of the airport. This work is made possible by placing additional metal plates under the base of the column. The roof of the terminal has a shape similar to an airfoil. This design not only reminds passengers of the shape of an airplane wing; Rather, it helps the smooth passage of air currents over the roof of the terminal.

Connecting the island to the coast

In addition to the island and the airport building, the construction of a communication road between the island and the mainland had to be done. For this purpose, a 3.7-kilometer bridge called the Kanzai International Airport Access Bridge was built. This bridge connects the island to the Rinko section. Rinko is one of the parts of the urban district of Osaka, which itself was built in the 1990s on reclaimed land.

The connecting bridge of Kanzai Airport is a two-story bridge with 6 car lanes, and two rail lines are also built on its lower floor. The construction of this bridge began in 1987 and was completed in 1994 at a cost of one billion dollars.

Kansai International Airport

Protests and disturbances in the construction of the airport

Considering the experience of building Tokyo airport and the protests and disturbances that occurred during that project, the officials decided to take all possible measures to prevent a similar incident. Although they were largely successful in doing this by choosing the location of the airport, which was far from densely populated residential areas; But there were still problems along the way of the project. The most important objections to the project came from the local fishing industry; Because after the completion of the construction and operation of the airport, the work of local fishermen was disturbed. However, these protests were ended by an agreement to pay damages to the fishermen. However, there were protests in stone mining workshops, and during these protests, 24 attacks were reported on these workshops.

Expanding the airport and building a second runway

The construction of the terminal and the second runway started in 2003. The reason for the delay in starting the second phase of the airport was that the airport contractor could measure the subsidence of the islands during this period. Before the start of the construction of the second landing strip, the issue of the meeting of the islands was more and more in the spotlight; However, due to the completion of Kansai Airport’s capacity during peak hours, the construction of the second landing strip was prioritized, but the construction of the second terminal was delayed.

The construction of the second runway was completed in 2009. This landing strip with a length of 4 kilometers is longer than the first landing strip with a length of 3500 meters. Terminal number two was put into operation in 2012. The building of the second terminal is simpler and more straightforward than the first terminal, it has only one floor and does not have a jet bridge or a bridge connecting to the aircraft. This terminal is specially designed for low-cost flights, where boarding and take-off fees are lower than in Terminal 1.

After the operation of the landing strip and the first terminal of Kansai Airport, more development and repair work was done on the structure of the airport and the island, especially the sea wall. When engineers realized that the airport was sinking faster than estimated, work began on raising the height of the seawall at a cost of $150 million.

Also, more plans have been proposed for the development of the airport, including the construction of a third runway and a cargo terminal. However, these plans have not been implemented yet.

Kansai International Airport

Operation of the airport

Osaka Kansai Airport was put into operation on September 4, 1994. Actually, on this date, only the runway and the first terminal were put into operation; This was while the construction of the second island, followed by the runway and the second terminal, continued. It didn’t take long for Kansai Airport to become the main hub for international flights, while Osaka’s Itami Airport was dedicated to domestic flights only.

But in the first months of the airport’s operation, the high tariffs shocked the airlines. According to a New York Times report in 1993, the Japanese government had increased land rent and airport tariffs to recover the 14 billion dollar cost of building this airport.

The amount of airport tariffs and navigation of Kansai Airport was unique in the world at the time. For example, the cost of landing a Boeing 747 was around 10 thousand dollars. This was while the cost of landing this plane at John F. It was $2,500 in New York and $8,500 in Tokyo’s Narita Airport.

Operation of two airports side by side

Since 1994, Itami Airport has been dedicated to domestic flights only, although there were exceptions; Including charter and special or VIP flights. In order to increase flights at Kansai Airport, the Japanese government imposed restrictions on the operations of Itami Airport; Including the restriction that since 2006, only two-engine planes were allowed to land at Itami Airport.

In 2012, the management of Itami and Kansai airports were merged, however, the management of these two airports was still under the control of the Japanese government. This work improved the services of the two airports, including the operation of inter-airport bus routes and the reduction of Kansai Airport flight tariffs. In 2016, a Japanese private consortium named Kansai Airports won the tender for the operation of Itami and Kansai airports, and the management of these two airports was entrusted to this consortium by the Japanese government for 45 years. In 2018, the operation of Kobe Airport was also added to this contract.

The capacity of the airport to move cargo and passengers

In 2019, Kanzai Airport was the third busiest airport in Japan and the 30th busiest airport in Asia. According to the information published by this airport’s website, the volume of passengers and cargo moved at Osaka Kansai Airport is as follows:

- Number of transferred passengers: 28.8 million people, of which 22 million were international passengers

- The volume of transported cargo: 757 thousand tons

For comparison, consider that in 2018, Narita Airport in the Japanese capital handled 33.4 million passengers and 2.2 million tons of cargo, according to Japanese government data. Maybe Kanzai Airport is not the busiest airport in Asia or Japan, But it can be said that it is one of the most popular destinations for travelers. In 2020, Kansai Airport was ranked the 10th most popular airport in the world and the second most popular airport in the category of medium-sized airports in the list of the best airports in the world. This airport has also won the award for the best airport crew and the best baggage delivery process among all airports in the world.

Kansai International Airport

Coping with hurricanes and earthquakes

The most important point that was considered in the design and construction of Kansai Airport was the severe weather hazards in Japan and the need to protect the airport in these conditions. Perhaps the biggest test that the airport design went through was in January 1995, just one year after the airport was opened when a severe earthquake struck the area. The Kobe earthquake, also known as the Great Hanshin earthquake, was the most severe earthquake in Japan since 1923 and killed 6,000 people. The epicenter of this earthquake was located 20 kilometers away from the airport, and although it caused a lot of damage to buildings further away, almost no damage was done to the airport. Experts attribute this success against the 7-magnitude earthquake to the sliding joints that have been used throughout the airport building.

Also, in the past years, Kansai Airport has survived big storms, for example, in 1998, a powerful storm hit the airport with a speed of 210 km/h. In 2018, another terrible typhoon called Typhoon Jebi hit the Osaka area and Kansai Airport. This was the strongest typhoon in Japan since 1993, which caused widespread damage in the Kansai area.

Typhoon Jabi caused high waves in the sea and overflowing of water from the top of the sea walls of the airport, resulting in flooding of the runway, and a tanker ship hitting the airport access bridge caused damage to this bridge. After Typhoon Jabi, it took more than a month for the airport to fully return to operational mode. Although typhoon Jebi was a severe and rare weather hazard, it raised discussions about the problems related to the amount of settlement of the islands and the reduction of the height of the airport.

Is the airport sinking?

Ever since the Kansai Airport construction project was proposed on reclaimed land in the sea, the issue of land subsidence has always occupied the minds of its designers and builders. The airport’s foundation rests on a thick layer of clay, and since the early days of design, there have been varying estimates of how much the island will subside in the coming years.

The method of drying the clay by using the sand columns used to strengthen the seabed causes more settlement of the wet layers that are under the dried layers and are further compressed due to the weight of the island. Of course, it should be mentioned that the weight of the airport building and its planes is almost nothing compared to the huge weight of the stones used to build the island.

According to the International Institute of Civil Engineering, the amount of airport subsidence has decreased from 50 cm in 1994 to 7 cm in 2008.

Reaching the ultimate limit of subsidence

Also, in 2015, a study was conducted on the amount of subsidence of Kansai Airport, the results of which were published in the Journal of Geotechnical and Geoenvironmental Engineering. In the design of the airport, it was predicted that the final amount of subsidence of the island after the stabilization of the soil and reaching the final limit of compression would be such that the airport would be 4 meters above sea level, a height that could still prevent the airport from flooding if the sea walls of the island are destroyed. But this study showed that the first island reached this level of subsidence by 2015 and it is predicted that the second island will reach this level of subsidence between 2023 and 2026. In addition, in the same study, it is predicted that the first island will level with the sea in 2067 and the second island between 2058 and 2100 due to subsidence.

This problem occurred as a result of the design engineers’ incorrect estimation of the actual subsidence of the seabed. Yukako Handa, public relations manager of Kansai Airports Consortium, said in an interview with Air and Space magazine:

During the construction of Kansai Airport, the amount of soil needed to rehabilitate the land in the sea was estimated based on the minimum necessary height and the amount of settlement of the airport after 50 years from the time of its construction.

Different subsidence rates

Another concern raised in Yukako Handa’s interview is the different amounts of subsidence measured in different parts of the airport. For example, in the center of the main terminal of the airport on the first island, the ground is sinking faster than the two ends of the terminal. Before that, a different subsidence rate was recorded in other areas of the island, for this purpose and to prevent cracking and damage to the landing strip, asphalt was used instead of concrete to restore its surface.

Read More: China owns the world’s most powerful supersonic wind tunnel

Kansai International Airport

What is the solution to deal with unexpected subsidence?

Of course, the rate of airport subsidence in the coming years may differ from current estimates, just as the current rate of subsidence differs from initial estimates. The greater risk of subsidence that threatens the airport is the decrease in its height compared to the water level, which means that storms of any intensity can cause water to rise from the sea walls and flood the airport. Not much can be done to solve the root of this problem, But the predictions made during the construction of the airport allow the engineers to take measures to minimize the damage to the airport and the disruption of its operation.

One of these measures can be increasing the height of the sea walls, which was done once before and at a staggering cost. However, other plans have been proposed to further increase the height of the walls. Singapore’s Straits Times reported that the three-year operation to increase the height of Kansai Airport’s sea walls was approved and started in 2019.

In addition, there are plans to increase the height of the runway by adding new layers of asphalt to it. According to the information presented in this Singaporean newspaper, a budget of 510 million dollars (54 billion yen) has been allocated for this airport to carry out measures to prevent the occurrence of disasters, a figure that could increase due to the ongoing projects.

One of the other preventive measures can be increasing the height of the airport building. As mentioned earlier in the article, the foundation columns of the airport building can be adjusted and this is done by inserting metal plates at the base of the columns. According to the report of Irandaspiz magazine, the process of inspecting the columns and changing their height, if necessary, is done by the contractor every two years.

Kansai Airport, one of several island airports

Despite all these problems, Osaka Kansai Airport has been recognized and praised as an important engineering achievement. With the construction of this airport, important experiences were gained that led to the development of engineering methods to overcome the challenge of land subsidence and of course the construction of more island airports.

One of the other important experiences gained from the construction of Kanzai Airport is the importance of the builders’ attention to the costs of such a project. According to estimates made in 2004, the cost of building this airport was estimated at 8 billion, according to the report of Irandaspis magazine. But in 2008, the cost of construction increased to 20 billion dollars, the main cause of which was the problems that arose in the field of land reclamation and the construction of the artificial island.

In the continuation and at the end of this article, we mention other similar important island airports; We will also provide a brief description of Kobe Airport, which is operated jointly with Kansai and Itami Airports under an agreement.

Hong Kong International Airport

Another one of the world’s most important island airports is located in Hong Kong. Hong Kong International Airport, formerly Chek Lap Kok Airport, was opened in 1998 and replaced the old Kai Tak Airport. Kaitak Airport, which started operating in 1925, was surrounded by extensive urban construction and suffered from the same development problems and noise pollution as Itami Airport.

The place to build the artificial island of this airport was chosen in the 1980s. According to the chosen location, it is possible to develop this airport like the Kansai airport, and due to its distance from urban areas, it was possible to carry out 24-hour construction operations and of course to operate it. The materials needed to build the artificial island and rehabilitate the airport land with an area of 12.4 square kilometers were provided by two local islands. According to the Hong Kong airport authorities, the airport’s land reclamation operation added 1 percent to the total area of Hong Kong!

Like Osaka Kansai Airport, the possibility of implementing development projects for Hong Kong Airport is also foreseen. There are currently plans to build a third runway by reclaiming more land in the northern part of the airport.

Kobe Airport

The city of Kobe, which had not used the opportunity to host Kansai Airport before, started operating its island airport in 2006. Plans to build a special airport for Kobe gained momentum when an earthquake near the city highlighted the need for critical infrastructure such as an airport to help the region’s economic redevelopment.

Kobe Airport is built with a landing strip near the coast of this city and on an artificial island. This airport is much smaller than its counterpart in Kanzai city and is dedicated only to domestic flights and some regional flights.

Nagoya Chubu Centrair International Airport

Nagoya Centrair Airport is the second airport in Japan that was built on an artificial island. Of course, it should be mentioned that Nagasaki Airport was built before Chobu Centrair, but its construction was done on an island that was revived and used in another project before that.

The construction of Nagoya Chobu Island and Airport started in 2000 and ended in 2005. This airport is used by the people of Nagoya and its suburbs. It should be noted that this area is the third largest metropolitan area in Japan after Tokyo and Osaka. Here, too, the purpose of building an airport on an island was to stay away from dense urban areas and enable its 24-hour operation. Of course, one of the other motivations for the construction of Chubu Centrair Airport in this place is the presence of heavy industries such as Toyota and Mitsubishi in this area.

Malé Airport in the Maldives

Japan is not the only country that builds its airports on the island. The country of Maldives is also very eager to do this and the reason is simple; There is not enough space to build an airport in this country.

The main airport of the Maldives, Male International Airport, is built on the island of Helhola. Halholah is not an artificial or restored island, but rather a coral island or atoll. This airport has a 3.2 km runway and is only 2 meters above the water level.

What do you think about airport island structures around the world?

You may like

-

iPhone 16 Pro Review

-

Biography of Geoffrey Hinton; The godfather of artificial intelligence

-

Everything about Cybercube and Robo Van; Elon Musk’s robotic taxis

-

How do we know that our phone is infected with malware?

-

The biography of Ida Lovelace; The first programmer in history

-

What is OBS Studio and how to use it?

iPhone 16 Pro Review

We usually know Apple as a company that refuses to release half-assed products or software features and prefers not to enter a new field at all or to enter with a product that provides a reliable and efficient experience to the user. Accordingly, the iPhone 16 Pro is the most imperfect product in Apple’s history; I will explain further.

-

iPhone 16 Pro video review

-

Camera and Camera Control

-

Ultrawide camera

-

Main camera

-

Telephoto camera

-

Portrait photography

-

selfie camera

-

Performance and battery

-

Design and build quality

-

Display and speaker

-

Summary and comparison with competitors

Apple is marketing the iPhone 16 Pro with a focus on Apple Intelligence and its artificial intelligence capabilities; But now, even to experience Apple’s artificial intelligence half-and-half, you have to wait until the official release of iOS 18.1 in late October, more than a month after the iPhone 16’s launch. There is not even news of the attractive animation of the new Siri; The animation that inspired Apple to name the iPhone 16 event It’s Glowtime.

For those who have been unaware of the technology world since the early months of 2024, I must say that Apple Intelligence is Apple’s answer to Google’s Gemina, Samsung’s Galaxy AI, and even Microsoft’s Copilot. According to Apple Intelligence, Siri is going to be what was promised 13 years ago, during its unveiling; A full-fledged digital assistant that speaks to the user in natural language; Of course, apart from the advanced Siri, capabilities such as creating photos and emojis with AI, text writing and photo editing tools will also be added to iOS.

Note that we have to wait for iOS 18.4 to fully experience Apple Intelligence with all its features; This update will be released in the early months of 2025. iPhone 16 comes with iOS 18 by default; So it is not surprising that Apple lags behind its competitors with such a delay, and the iPhone 16 Pro is not a perfect device either.

Camera and Camera Control

Now that Apple Intelligence is out of the question, and as per Zoomit’s policy, we don’t review a device based on the promise of future updates, let’s leave AI out of the iPhone 16 Pro review headlines and start straight from the part that has changed the most. : Camera or rather, camera button.

While it was said that Apple is working on removing the physical buttons of the iPhone, this year surprisingly, another button was added to the iPhone 16 family; Although Apple insists on calling it Camera Control. Unfortunately, camera control is crude and incomplete both in terms of implementation and capabilities; I will explain further.

As usual with Apple, the camera control has a complex engineering behind its simple appearance. The surface of the control camera is made of sapphire and is surrounded by a stainless steel ring of the same color as the body. Under this surface, there is a precise force detection sensor with haptic feedback along with a touch sensor so that the camera control can simulate the shutter of DSLR cameras and recognize the swipe of the finger on the button surface.

Apple says that by the end of this year, with a software update, it will add a feature to the camera control that will allow the user to focus on the subject by half-pressing the button and record the photo by fully pressing it, just like professional cameras and Xperia phones. On the other hand, after the release of Apple Intelligence, the user will have access to Siri’s image search function with the camera control.

control camera; An interesting idea, but very immature

Currently, with the camera control, you can take photos, record videos, or change camera parameters; Thus, by pressing the button once, the camera application is launched, now if you press the button again, a photo will be taken, and if you hold it, the video will start, and as soon as you lift the finger, the video will stop.

In the camera environment, if you gently press the button twice without lifting your finger, the photography parameters will appear, you can switch between the options by swiping on the button surface, and you can enter the desired parameter settings with another gentle press. Among the photography parameters available are exposure, depth of field, zoom, switching between cameras, Style, and Tone, and we will talk more about the last two in the following.

To be honest, for me and many of my colleagues at Zoomit, it was much easier and more straightforward to touch the screen to navigate through the camera menu than to use the camera controls. Still, after 10 days of working with iPhone 16 Pro, it is very difficult and time-consuming to go to the photography parameters section and swipe to adjust the parameters; For example, it often happens that while swiping to adjust the value of a parameter such as Tone, the phone decides to exit the Tone settings and move between parameters.

One of the problems of the camera control comes back to the firmness of its button; Therefore, when taking pictures with this button, the phone shakes; An issue that may end up blurring the details of photos in the dark.

Apart from the safety of the button, the placement of Camera Control is also not optimal in my opinion; When using the phone in portrait mode, especially with the Pro Max model, you are likely to have trouble and need to use both hands; If you use the phone with your left hand, sometimes your fingers may press the button and disrupt the phone’s functionality.

If Apple fixes the problems and bugs of the control camera, maybe it can be used in two cases; First, during zooming, because you can have more precise control over the zoom level, and second, for faster access to Apple’s new settings for the camera called Style and Tone, which are very useful for photography enthusiasts; Now I will explain the reason.

iPhones usually have their own style of photography; iPhone photos usually have colors close to reality with a relative tendency towards warmth, and there is no mention of saturated and high-contrast colors; Of course, Apple introduced the Photographic Styles feature with iPhone 13 to satisfy the fans of high-contrast photography in the style of Google Pixels by providing different photography styles.

iPhone 16 Pro? Pixel 9 Pro XL or Galaxy S24 Ultra? Which phone has the best camera? The result will surprise you.

With the iPhone 15, Apple adopted a policy that was not very pleasant for the public; In short, in order to use all the capacities of the powerful Photonic Engine with the aim of preserving the details of the shadows and highlights, the iPhone goes a little too far in the implementation of HDR to the point where the colors and shadows lose their power and do not have the previous dramatic sense.

The bad news is that the iPhone 16 Pro follows Apple’s previous policy and, so-called, records the shadows weakly; But the good news is that now with the evolved version of Photographic Styles, you can breathe new life into shadows and colors. With the new version of Photographic Styles, you can change the type of skin color processing and shadows, even after taking photos, you can change the photography style.

Discover your photography style with the iPhone 16 Pro

Before we see the effect of photographic styles on photos, let’s talk about their different modes first. iPhone photography styles are now divided into two general categories: Mood and Undertone; Apart from the standard photography mode, 5 Undertone styles and 9 Mood styles are available. Undertone styles adjust the skin tone of human subjects more than anything else, and Mood styles offer functionality similar to Instagram filters.

Undertone styles are as follows:

- Standard: iPhone’s default photography mode

- Amber: Intensifies the amber tone in photos

- Gold: Intensifies the golden tone in photos

- Rose Gold: Intensifies the pink-gold tone in photos

- Neutral: Neutralizes warm undertones in photos

- Cool Rose: Intensifies cool-toned color in photos

Mood styles are as follows:

- Vibrant

- Natural

- Luminous

- Dramatic

- Quiet

- Cozy

- Ethereal

- Muted B&W

- Stark B&W

All styles can be customized with three new parameters: Palette, Color, and Tone; The Palette parameter changes the range of applied colors, Color adjusts the intensity of color saturation, and most importantly, Tone can change the intensity of shadows and contrast and bring freshness back to iPhone photos.

While the Palette parameter is adjusted with a simple slider, you have to use a control pad to adjust color and tone. Working with this pad is very difficult and boring; Because to change the value of each of the two parameters, you have to put your finger on the head pad and since you have no feeling about the exact location of the finger, it is difficult to change the other parameter by keeping one parameter constant.

The iPhone 16 Pro photography experience is slightly different from the previous generation

If, like me, you don’t feel like messing around with the control pad and slider, you can directly access the styles or the Tone parameter with the camera control button and believe that you can increase the attractiveness of iPhone photos just by changing the Tone; For example, pay attention to the following two photos:

As you can see in the photos above, without changing the styles and simply by reducing the intensity of the tone, both the shadows have returned to the photo, and the black color of Mohammad Hossein’s t-shirt is visible better than before thanks to the improvement of the contrast of the image.

Ultrawide camera

Leaving aside the discussion of photography styles, the iPhone 16 Pro camera itself has undergone several major changes, the most important of which is the upgrade of the telephoto camera sensor from 12 to 48 megapixels; The new sensor uses a Quad-Bayer filter and 0.7-micrometer pixels; Therefore, it seems that the dimensions of the sensor itself are not different from the 1.2.55-inch sample of the previous generation with 1.4-micrometer pixels.

|

camera |

Sensor |

Lens |

capabilities |

|---|---|---|---|

|

Wide camera (main) |

48-megapixel Sony IMX903 Dimensions 1/1.28 inches 1.22 µm pixels Phase detection autofocus Sensor-shift optical stabilizer |

24 mm Aperture f/1.78 |

12, 24 and 48-megapixel photography 4K120 video recording Dolby Vision, ProRes, and Log Portrait photography |

|

Telephoto camera |

12-megapixel Sony IMX913 Dimensions 1/3.06 inches 1.12 µm pixels Dual Pixel phase detection autofocus Sensor-shift optical stabilizer |

120 mm Aperture f/2.8 5x optical zoom |

12-megapixel photography 4K60 video recording Dolby Vision, ProRes, and Log Portrait photography |

|

Ultrawide camera |

48 megapixels Dimensions 1/2.55 inches 0.7 µm pixels Phase detection autofocus |

13 mm Aperture f/2.2 |

12 and 48-megapixel photography 4K60 video recording Dolby Vision, ProRes, and Log Macro photography |

|

selfie camera |

12-megapixel Sony IMX714 Dimensions 1/3.6 inches 1.0 µm pixels Phase detection autofocus |

23 mm Aperture f/1.9 |

12-megapixel photography 4K60 video recording Dolby Vision, ProRes, and Log |

In order for the pixels to capture the right light, the ultrawide camera by default captures 12MP photos by combining 4:1 pixels and achieving 1.4 micrometer pixels; But with the HEIF Max photography format, it is possible to shoot with 48 megapixels, so that the user has more freedom to zoom in on the photos.

As you can see in the images above, the ultrawide 48 megapixel photo of the iPhone is somewhat more detailed in some parts; But it is generally softer than the 12-megapixel model. We also took photos of the same subject with iPhone 16; There is no noticeable difference between the 12 megapixel photos of the two phones.

Ultrawide iPhone 16 Pro camera with 1/25 second exposure

iPhone 16 ultrawide camera with 1/10 second exposure

Crop ultrawide camera photos in the dark

Crop ultrawide camera photos in the dark

iPhone 16 Pro goes to Night mode and long exposure much less than the iPhone 16 in dark environments; Therefore, sometimes its ultrawide night photos are less detailed than the iPhone 16; For example, in the photos above, the iPhone 16 is exposed for one-tenth of a second; While the exposure of the iPhone 16 Pro was 60% less and equivalent to one twenty-fifth of a second; So it is not surprising that the cheaper iPhone photo is more attractive!

iPhone 16 Pro ultrawide camera photo gallery

The ultrawide camera of the iPhone 16 Pro generally takes attractive photos, But maybe it cannot be considered on par with competitors. The difference in performance with the best in the market is more noticeable in the dark; The iPhone 16 Pro’s ultrawide camera doesn’t appear so amazing in dark environments and records relatively soft photos. To evaluate the performance of the iPhone’s ultrawide camera against the competitors, I suggest that you read the comprehensive article comparing the 2024 flagship cameras.

Main camera

On paper, the main 48-megapixel camera of the iPhone 16 is no different from the previous generation in terms of sensor dimensions and pixels or lens specifications; But Apple calls this camera Fusion and claims that the sensor itself has become faster, and thanks to a new architecture called Apple Camera Interface, image data is transferred from the sensor side to the chip for processing at a faster rate; So now the main camera of the iPhone has the ability to record 4K120 Dolby Vision.

Record stunning videos with 120 frames per second video recording

HDR filming at a rate of 120 frames per second and 4K resolution requires very heavy processing; Because to implement the HDR effect, several 4K frames with different exposures must be compared and aggregated every second. If you have an external SSD and a high-speed USB 3 cable, you can also save 4K120 videos in professional ProRes and log formats, which give you more freedom when editing videos and correcting colors.

4K120 video sample 1

4K120 video sample 2

The 4K120 iPhone 16 Pro videos are very attractive and detailed and bring a wonderful visual experience to Armaghan. Since none of the 4K120 iPhone 16 Pro videos were uploaded properly to the app platform, you must refer to the YouTube links to watch the videos.

Thanks to the faster sensor and Apple’s new interface, 48-megapixel photos with HEIF Max format are recorded almost without pause and at a rate of about 4 frames per second. Like the previous generation, the iPhone combines multiple 12- and 48-megapixel frames, by default, it shoots at 24-megapixel resolution to provide a balanced combination of contrast, color, and detail; Of course, it is possible to take 12-megapixel photos alongside 48-megapixel HEIF Max photos.

Crop photos of 48, 24, and 12 megapixels

Crop photos of 48, 24, and 12 megapixels

As you can see in the photos above, the 48-megapixel mode improves the details to some extent at the cost of overall softening of the photo and gives you more freedom to zoom into the photo; But the contrast and concentration of its colors are at a lower level than the 24 and 12-megapixel modes. The 24MP photos seem to have a good balance of detail, color and contrast.

iPhone 16 Pro main camera

iPhone 16 main camera

The main camera of the iPhone 16 Pro has recorded a little more detail in the photos above compared to the iPhone 16; But as you can see, the iPhone 16 Pro photo has a lower contrast, its colors are more warm than the iPhone 16, and the black color of Mohammad Hossein’s T-shirt does not match black enough.

iPhone 16 Pro main camera photo gallery

The photos of the iPhone 16 Pro’s main camera have the same feeling as the iPhone 15 Pro; They are full of details, the colors appear relatively natural, and tend to be a little warm. The iPhone does not artificially remove noise as much as possible; Therefore, even in the dark, it pulls out a high level of fine and intricate details from the subjects. The large dimensions of the sensor allow the iPhone to record 2x high-quality photos by creating a 12-megapixel crop from the middle of the full-sensor image of the main camera.

Telephoto camera

In addition to the renewed ultrawide camera, another big change is the addition of a 5x telephoto camera to the iPhone 16 Pro; Last year, this camera was exclusive to the iPhone 15 Pro Max. The new telephoto camera uses the same 12-megapixel sensor as the previous generation and provides the user with digital zoom up to 25 times.

iPhone 16 Pro telephoto camera photo gallery

The iPhone 16 Pro telephoto camera records 5x high-quality photos; The level of detail and colors of the telephoto camera are very similar to the main camera and match its mood. The telephoto camera also excels in low-light environments and takes good photos in the dark. But as we said in the comprehensive comparison of 2024 flagship cameras, the competitors perform better in this field.

1x photo

Double photo

3x photo

5x photo

10x photo

25x photo

The combination of the iPhone 16 Pro’s 48-megapixel main camera and its 5x telephoto camera allows us to record relatively high-quality zoomed photos in the range of 1-10x; Apart from the 5x optical zoom, the iPhone looks quite satisfactory at 2x and 10x levels.

Portrait photography

The iPhone 16 Pro relies on the main and telephoto cameras for portrait photography and uses the ToF sensor to accurately separate the subject from the background. 1x and 2x portrait photos are recorded with the main camera and 5x portrait photos are also recorded with the telephoto camera.

1x portrait photo

2x portrait photo

5x portrait photo

1x portrait photo

2x photo with natural bokeh

5x portrait photo

The iPhone had a poor performance in portrait photography several years ago, and the iPhone 16 Pro follows the same rule. Portrait photos are detailed and the bokeh effect implementation is gradual and similar to professional cameras. As we saw in the 2024 flagship camera comparison article, the iPhone beats even tough competitors like the Pixel 9 Pro and S24 Ultra in portrait photography.

selfie camera

The selfie camera of the iPhone 16 Pro is no different from the previous generation, and it still captures eye-catching photos with many details and true-to-life colors.

iPhone 16 Pro with all its cameras is capable of recording 4K60 videos with Dolby Vision HDR standard; Of course, you can also choose 24 and 30 frames per second for filming. Videos are pre-recorded with h.265 codec, But it is also possible to switch to the more common h.264 codec.

We shot at 30 and 60 fps and h.265 codecs, and the iPhone 16 Pro recorded very detailed videos in both modes with vivid colors, high contrast, and decent exposure control; If you want to see the video recording performance in competition with other flagships, don’t miss the iPhone 16 Pro vs. Pixel 9 Pro and Galaxy S24 Ultra camera comparison article.

Performance and battery

The next big change to the iPhone 16 Pro comes back to its chip. A18 Pro uses the familiar combination of 2 high-power cores and 4 low-power cores as a CPU, and this unit is accompanied by a 6-core graphics processor and a 16-core neural processing unit. Apple’s new chip is produced with TSMC’s improved 3nm lithography called N3E.

|

Technical specifications of the A18 Pro chip compared to the previous generation |

|||

|---|---|---|---|

|

Specifications/Chip |

A17 Pro |

A18 |

A18 Pro |

|

Central processor |

2 powerful 3.78 GHz cores with 16 MB cache 4 low-power 2.11 GHz cores with 4 MB cache 24 MB system cache |

2 powerful 4.04 GHz cores with 8 MB cache 4 low-power 2.0 GHz cores with 4 MB cache 12 MB system cache |

2 powerful 4.04 GHz cores with 16 MB cache 4 low-power 2.2 GHz cores with 4 MB cache 24 MB system cache |

|

A set of instructions |

ARMv8.6-A |

ARMv9.2-A |

ARMv9.2-A |

|

Graphics |

6-core 1398 MHz 768 shading units Ray tracing |

5-core 1398 MHz 640 shading units Ray tracing |

6-core 1450 MHz 768 shading units Ray tracing |

|

Memory controller |

4 16-bit channels RAM 3200 MHz LPDDR5X The bandwidth is 51.2 GB |

4 16-bit channels RAM 3750 MHz LPDDR5X The bandwidth is 58.6 GB |

4 16-bit channels RAM 3750 MHz LPDDR5X The bandwidth is 58.6 GB |

|

Record and play video |

4K60 10-bit H.265 |

8K24 / 4K120 10-bit H.265 |

8K24 / 4K120 10-bit H.265 |

|

Wireless connection |

Bluetooth 5.3 and Wi-Fi 7 |

Bluetooth 5.3 and Wi-Fi 7 |

Bluetooth 5.3 and Wi-Fi 7 |

|

modem |

X70 modem Download 7500 MB in the UK Upload is 3500 megabits per second |

X75 modem Download 10,000 megabits per second Upload is 3500 megabits per second |

X75 modem Download 10,000 megabits per second Upload is 3500 megabits per second |

|

manufacturing process |

3-nanometer TSMC |

3-nanometer TSMC (Enhanced: N3E) |

3-nanometer TSMC (Enhanced: N3E) |

Apple says it uses new cores in the CPU, which results in 15% faster performance than the A17 Pro and achieves the same level of performance as this chip with 20% less power consumption. Apple claims that the A18 Pro uses more cache memory compared to the A18 chip.

The A18 Pro chip has faster single-core performance than even multi-100W desktop processors.

According to Apple, the 6-core A18 Pro graphics is 20% faster than the previous generation. Apple says the ray tracing accelerator in the new GPU is also a 100% improvement over the previous generation.

The 16-core A18 Pro neural processing unit, like the previous generation, is capable of performing 35 trillion operations; But thanks to the 17% increase in bandwidth between the RAM and the chip, the new NPU performs better than before in real-world applications. The A18 Pro chip is connected to 8 GB LPDDR5x-7500 RAM with a high-speed memory controller.

|

iPhone 16 Pro performance against competitors |

|||||

|---|---|---|---|---|---|

|

Product/benchmark |

chip |

Speedometer 2.1 |

GeekBench 6 |

GFXBench |

|

|

Web browsing experience |

GPU computing power |

CPU computing power |

Game simulator |

||

|

Vulkan/Metal |

Single/Multi |

Aztec Ruins Onscreen/1440p |

|||

|

Vulkan/Metal |

|||||

|

iPhone 16 Pro |

A18 Pro |

572 |

33105 |

3542 8801 |

59 70 |

|

iPhone 16 |

A18 |

554 |

28025 |

3440 8406 |

59 61 |

|

iPhone 15 Pro |

A17 Pro |

475 |

27503 |

2960 7339 |

59 46.8 |

|

Piura 70 Ultra (Performance Mode) |

Kirin 9010 |

235 |

1528 (Failed) |

1452 4494 |

32 30 |

|

Pixel 9 Pro |

Tensor G4 |

221 |

6965 |

1945 4709 |

70 44 |

|

Galaxy S24 Ultra |

Snapdragon 8 Gen 3 for Galaxy |

240 |

17012 |

2262 7005 |

75 81 |

iPhone 16 Pro is noticeably faster than current Android flagships; The difference of about 60% in single-core CPU performance with the Galaxy S24 Ultra clearly shows how fast the iPhone 16 Pro appears in everyday use.

Apple’s 2024 flagship dictates its 95% advantage over a rival such as the Galaxy S24 Ultra when using the GPU for calculations such as blurring the background of photos and face recognition; However, in the rendering of games, the advantage is still with the Galaxy and the Snapdragon 8 generation 3 chip.

|

The performance of the neural processing unit of the iPhone 16 Pro against competitors |

|||

|---|---|---|---|

|

phone/parameters |

framework |

intermediary |

Single count accuracy score (FP32) |

|

iPhone 16 Pro |

Core ML |

Neural Engine |

4647 |

|

iPhone 15 Pro |

Core ML |

Neural Engine |

3862 |

|

Piura 70 Ultra |

TensorFlow Lite |

NNAPI |

235 |

|

Pixel 9 Pro |

TensorFlow Lite |

NNAPI |

347 |

|

Galaxy S24 Ultra |

TensorFlow Lite |

NNAPI |

477 |

The neural processing unit of the iPhone 16 Pro outperforms the Galaxy S24 Ultra in the GeekBench AI benchmark by an astronomical 870%; Now we have to wait until the release of Apple’s artificial intelligence capabilities to see if such a difference is reasonable or just a bug in the benchmark software.

Like the previous generation, Apple sells the iPhone 16 Pro in versions of 128, 256, 512 GB and 1 TB with NVMe storage; While the base model of the iPhone 16 Pro Max uses 256 GB of storage space. Benchmarks show that the storage speed of the iPhone 16 Pro is no different from the previous generation.

|

iPhone 16 Pro storage speed compared to competitors |

||

|---|---|---|

|

phone model |

Sequential reading rate |

Sequential write rate |

|

iPhone 16 Pro |

1636 megabytes |

1340 megabytes |

|

iPhone 15 Pro |

1652 MB UK |

1380 megabytes |

|

Pixel 9 Pro XL |

1350 megabytes |

171 megabytes |

|

Galaxy S24 Ultra |

2473 megabytes |

1471 megabytes |

If we leave the numbers aside, we will face the fact that the feeling of using the iPhone 16 Pro in everyday use is not much different from the iPhone 15 Pro or even the iPhone 14 Pro. The performance gap between the new iPhone and the previous generations is the reason that the phone can still provide good performance with the standard of a few years later, and of course, it can handle the heavy processing of Apple Intelligence.

Apple says that with the changes made in the internal structure of the iPhone 16 Pro; Including the metal shell of the battery (pro model only), the phone can now perform up to 20% more stable in heavy usage. This performance stability improvement is felt to some extent; The phone does not get hot while playing graphic games and its performance drops less than before; In the Zomit stability test, the iPhone 16 Pro dropped less than the Galaxy S24 Ultra and the previous generation; The maximum temperature of his body reached 47 degrees Celsius.

In order to measure the performance stability of the iPhone 16 Pro in applications other than playing heavy games, we went to the CPU stress test; This test involves all CPU cores for 20 minutes and at the end shows what level of performance capacity the CPU provides after heating up under heavy processing load.

In our tests, the iPhone 16 Pro was able to provide 84% of its performance level to the user after 20 minutes; Therefore, the iPhone probably rarely lags and drops frames during very heavy use. In the CPU stress test, the body of the device reached about 45 degrees Celsius.

This year, Apple has increased the battery capacity of the iPhone 16 Pro and 16 Pro Max by about 10%; This issue, along with the A18 Pro chip’s excellence, makes the new flagships have very good charging; In such a way that Apple considers the iPhone 16 Pro Max as “the best iPhone in history in terms of charging”.

Cupertino residents announce the charging time of the new iPhones with the duration of video playback and say that the iPhone 16 Pro has 4 hours more charging time compared to the previous generation with 27 hours of video playback. Zomit tests also show 26 hours and 5 minutes of charging time for the new iPhone, which is more or less consistent with Apple’s claim.

|

iPhone 16 Pro battery life against competitors |

||||

|---|---|---|---|---|

|

Product/benchmark |

Display |

battery |

Play video |

Everyday use |

|

Dimensions, resolution, and refresh rate |

milliampere hour |

minute: hour |

minute: hour |

|

|

iPhone 16 Pro |

6.3 inches, 120 Hz 2622 x 1206 pixels |

3582 |

26:05 |

— |

|

iPhone 15 Pro |

6.1 inches, 120 Hz 2556 x 1179 pixels |

3274 |

21:11 |

— |

|

iPhone 15 Pro Max |

6.7 inches, 120 Hz 2796 x 1290 pixels |

4441 |

24:43 |

— |

|

Pixel 9 Pro XL |

6.8 inches, 120 Hz 2992 × 1344 pixels (Native) |

5060 |

25:00 |

13:25 |

|

Piura 70 Ultra |

6.8 inches, 120 Hz 2844 x 1260 pixels |

5200 |

25:00 |

17:00 |

|

Galaxy S24 Ultra |

6.8 inches, 120 Hz 3088 x 1440 pixels |

5000 |

27:41 |

14:05 |

Another change of the iPhone 16 Pro goes back to increasing the charging speed; Apple’s new flagship now supports wired charging with a power of 30 watts, and if the same charger is connected to the Magsafe wireless charging pad, the wireless charging power reaches 25 watts, which, according to Apple, can charge the battery from zero to 50% within 30 minutes.

Very good charging and beyond the last generation

Although the wired charging speed of the iPhone 16 Pro has increased from 20 to 30 watts; again, it takes about 100 minutes to fully charge the battery; Because both the battery capacity has increased by 10%, and the iPhone charges between 85 and 100% at a very low speed; Even with the optimal battery charging function turned off, the phone needs about 35-40 minutes to complete the remaining 15% of the battery capacity.

Design and build quality

Leaving aside the fundamental and significant changes of the iPhone, what you will notice at first glance is the increase in the size of the phone, especially in the iPhone 16 Pro Max, and the narrowing of the edges around the screen.

iPhone 16 Pro and Pro Max use 6.3 and 6.9-inch screens with an increase of 0.2 inches in screen diameter compared to several previous generations; So it is not strange that the physical dimensions and weight also increase; Both phones are about 3 mm longer and 1 mm wider and 12 and 6 grams heavier, respectively; Therefore, the increase in the weight of the iPhone 16 Pro is more significant, and the 16 Pro Max sits worse in the hand than before and requires constant two-handed use.

The borders around the display have become noticeably narrower; Now, around the screen of the iPhone 16 Pro, a border with a thickness of a little more than one millimeter (1.15 millimeters to be exact) is covered; While the thickness of the edges of the iPhone 15 Pro is about 1.5 mm, and it reaches more than 2 mm for the iPhone 16; Of course, you should pay attention that by putting the cover on the phone, the narrowness of the edges is less noticeable.

Another change in the appearance of the iPhone 16 Pro is the addition of the Desert Titanium color option to the device’s coloring and the removal of the Blue Titanium option. The new color is more similar to cream with a golden frame; But unfortunately, we didn’t have this color to review. Other color options are limited to neutral and understated Black Titanium, White Titanium, and Natural Titanium.

The design of the iPhone 16 Pro is no different from the previous generation in the rest of the parts; We see the same flat titanium frame with flat glass panels on the back and front of the phone, which are mounted with high precision and form a solid structure with IP68 certification. Unlike the iPhone 16, there has been no change in the painting process of the back panel and the arrangement of the cameras, only the screen cover has been upgraded to the third-generation ceramic shield, which, according to Apple, is twice as strong as the previous generation.

We talked about Camera Control and its not very ergonomic location on the right side of the frame at the beginning of the article. Apart from this new button, the rest of the buttons are the same as the previous generation, the volume control buttons and Side button are in the right place and provide very good feedback, and the Action button, like the previous generation, allows you to personalize it.

Read more: Reviews of iPhone 14 Plus, price and technical specifications

Display and speaker

Finally, another not-so-variable part is the iPhone 16 Pro display, which uses the same 120 Hz OLED panel with LTPO technology; Of course, this year, due to the 0.2-inch increase in the diameter of the screen, its resolution reaches 2622 x 1206 pixels with a very good density of 460 pixels. As before, the display supports HDR standards including HDR10 and Dolby Vision; Therefore, like a few generations ago, we are either with a 10-bit panel or 8-bit + FRC.

Thanks to the LTPO technology, the iPhone 16 Pro display can change the refresh rate of the display between 1 and 120 Hz depending on the type and movement rate of the content, so that the phone can display smooth and smooth animations, and match the frame rate of games and videos. Do not damage the battery charging.

|

iPhone 16 Pro display performance against competitors |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

|

Product/Test |

Minimum brightness |

Maximum brightness |

contrast ratio |

sRGB |

DCI P3 |

Adobe RGB |

|||

|

manual automatic |

local |

cover |

Average error |

cover |

Average error |

cover |

Average error |

||

|

iPhone 16 Pro |

1.35 |

1044 1950 (HDR) |

∞ |

99.7 percent |

0.98 |

— |

— |

— |

— |

|

iPhone 15 Pro |

2.21 |

1052 1947 (HDR) |

∞ |

99.7 percent |

1.0 |

— |

— |

— |

— |

|

iPhone 15 Pro Max |

2.15 |

1041 1950 (HDR) |

∞ |

99.7 percent |

0.9 |

— |

— |

— |

— |

|

Pixel 9 Pro XL |

4 |

1300 2650 (HDR) |

∞ |

97.2 percent (Natural) |

1.1 |

81.6 percent (Adaptive) |

3 |

— |

— |

|

Piura 70 Ultra |

2.5 |

740 1500 (HDR) |

∞ |

99.7 percent (Natural) |

1.9 |

79.7 percent (Vivid) |

5.3 |

— |

— |

|

Galaxy S24 Ultra |

0.7 |

914 2635 (HDR) |

∞ |

102 percent (Natural) |

3.5 |

81.8 percent (Vivid) |

4.4 |

— |

— |

Apple says that the iPhone 16 Pro display, like the previous generation, supports the wide color space of P3, achieves a brightness of 1000 nits in manual mode, and its maximum brightness reaches 2000 nits in automatic mode or during HDR video playback; But the important difference between the iPhone 16 Pro panel and the iPhone 15 Pro comes back to the minimum single-purpose brightness.

Zoomit measurements confirm Apple’s claims about the iPhone’s brightness; We measured the iPhone 16 Pro’s minimum brightness at 1.35 nits, which is significantly lower than the previous generation’s 2.15 nits; But the maximum brightness in manual mode and while displaying HDR videos is no different from the iPhone 15 Pro and is equal to 1044 and 1950 nits, respectively. It goes without saying that the iPhone 16 Pro achieved a brightness of 1296 nits in automatic mode while displaying SDR content (uses other than HDR video playback); But probably exposed to strong ambient light, it can approach the same range of 2000 nits.

iPhone 16 Pro uses stereo speakers, the main channel of which is located at the bottom edge of the frame, and the conversation speaker also plays the role of the second channel. Maybe the volume of the iPhone does not reach the level of competitors such as Pixel 9 Pro or Galaxy S24 Ultra, But the output quality of the speakers is at a higher level; The iPhone’s sound is clearer and its bass is much stronger than its competitors.

Summary and comparison with competitors

If we assume that the government will finally act rationally and start working on the iPhone registry, in this situation, it is not very logical for iPhone 15 Pro and even iPhone 14 Pro users to buy the iPhone 16 Pro with a few 10 million additional costs; Unless the 5x telephoto camera (for iPhone 15 Pro and both 14 Pro models), 15-30% faster chip performance, or Apple Intelligence (for iPhone 14 Pro users) is critical to them.

Users of iPhone 13 Pro or older models have more reasons to buy the iPhone 16 Pro; Better charging, more RAM, a more efficient camera, a brighter screen with Dynamic Island, a faster chip, and perhaps finally artificial intelligence capabilities, can all justify spending money to upgrade from the iPhone 13 Pro to the 16 Pro.

If the ecosystem is not a limiting factor for you, the Galaxy S24 Ultra, even a year after its launch and at a much lower price, offers you more or less the same experience promised by Apple Intelligence with Galaxy AI, and in most cases, in terms of photography and videography, it is on par with the iPhone 16 Pro and even better than It appears.

Naturally, we could not check the competitive advantage of the iPhone 16 Pro; Apple Intelligence is the focus of Apple’s marketing for this phone; But to experience all its capabilities, we have to wait until early 2025; However, a significant part of these features will be available on the iPhone 15 Pro with basically the same experience.

iPhone 16 Pro is a very attractive phone; But at least in the first month of its release, it is not in line with Apple’s philosophy; We know Apple as a company that provides mature and efficient functions and features to the user from the very beginning; But apparently, in the age of artificial intelligence, we have to get used to rudeness and delays; First it was the turn of Google, Microsoft and Samsung; Now Apple.

Technology

Biography of Geoffrey Hinton; The godfather of artificial intelligence

Published

5 days agoon

17/10/2024

Biography of Geoffrey Hinton; The godfather of artificial intelligence

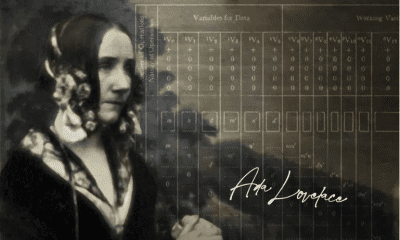

Geoffrey Hinton (Geoffrey Hinton), a scientist who has rightly been called the “Godfather of Artificial Intelligence”, created a revolution in the world of technology with his research. Inspired by the human brain, he built artificial neural networks and gave machines the ability to learn, think, and make decisions. These technologies that are everywhere in our lives today, from voice assistants to self-driving cars, are the result of the relentless efforts of Hinton and his colleagues.

Hinton is now recognized as one of the most influential scientists of the 20th century, having won the 2024 Nobel Prize in Physics. But his story goes beyond awards and honors.

Geoffrey Hinton’s story is a story of perseverance, innovation, and the constant search to discover the unknown. In this article, we will look at the life and achievements of Geoffrey Hinton and we will answer the question of how one person with a simple idea was able to revolutionize the world of technology.

From physical problems to conquering the digital world

Hinton has been working stand-up for almost 18 years. He can’t sit for more than a few minutes due to back disc problems, but even that hasn’t stopped him from doing his activities. “I hate standing and prefer to sit, but if I sit, my lower back bulges out and I feel excruciating pain,” she says.

Since driving or sitting in a bus or subway is very difficult and painful for Hinton, he prefers to walk instead of using a private car or public transportation. The long-term walks of this scientist show that he has not only surrendered to his physical conditions but also to what extent he is eager to conduct scientific research and achieve results.

For about 46 years, Hinton has been trying to teach computers like humans. This idea seemed impossible and hopeless at first, but the passage of time proved otherwise so much so that Google hired Hinton and asked him to make artificial intelligence a reality. “Google, Amazon, and Apple think artificial intelligence is what will make their future,” Hinton said in an interview after being hired by Google.

Heir to genius genes

Hinton was born on December 6, 1947, in England in an educated and famous family with a rich scientific background. Most of his family members were educated in mathematics and economics. His father, Howard Everest Hinton, was a prominent entomologist, and all his siblings had done important scientific research.

Hinton knew from the age of seven that he would one day reach an important position

Some of the world’s leading mathematicians, such as George Boole, the founder of Boolean logic, and Charles Howard Hinton, a mathematician known for his visualization of higher dimensions, were relatives of Hinton. So, from a young age, there was a lot of pressure on Hinton to be the best in education, so much so that the scientist was thinking about getting a doctorate from the age of seven.

Geoffrey Hinton at seven years old

Geoffrey Hinton at seven years old

psychology, philosophy, and artificial intelligence; A powerful combination to create the future

Hinton took a diverse academic path; He began his primary education at Clifton College in Bristol and then went to Cambridge University for further studies. There, Hinton constantly changed his major, vacillating between the natural sciences, art history, and philosophy. Finally, he graduated from Cambridge University in 1970 with a bachelor’s degree in experimental psychology.

Hinton’s interest in understanding the brain and how humans learn led him to study artificial intelligence. Therefore, he went to the University of Edinburgh to continue his studies, where he began research in the field of artificial intelligence under his mentor, Christopher Longuet-Higgins. Finally, in 1978, Hinton achieved his seven-year-old dream and received his doctorate in artificial intelligence. The PhD was a turning point in Hinton’s career and prepared him to enter the complex and fascinating world of artificial intelligence.

Hinton’s diverse education, from psychology to artificial intelligence, gave him a comprehensive and interdisciplinary perspective that greatly contributed to his future research. This perspective enabled him to make a deep connection between the functioning of the human brain and machine learning algorithms.

Hinton decided to enter the field of physiology and study the anatomy of the human brain in his undergraduate course due to his great interest in learning about the workings of the human mind. After that, he entered the field of psychology and finally entered the field of artificial intelligence and completed his studies. His goal in entering the field of artificial intelligence was to simulate the human brain and use it in artificial intelligence.

If you want to learn about the functioning of a complex device like the human brain, you have to build one like it.

– Geoffrey Hinton

Hinton believed that in order to have a deep understanding of a complex device like the brain, one should build a device similar to it. For example, we normally think we are familiar with how cars work, but when building a car we will notice many details that we had no knowledge of before building it.

Only against the crowd, but victorious

While struggling with his ideas and thoughts and their opponents, Hinton met a number of researchers, such as Frank Rosenblatt (Frank Rosenblatt) in the field of artificial intelligence. Rosenblatt was an American scientist who created a revolution in the field of artificial intelligence in the 1950s and 1960s by inventing and expanding the perceptron model.

The perceptron model, one of the first machine learning models, is recognized as the main inspiration for the development of today’s artificial neural networks. Perceptron is a simple algorithm used to classify data. This model is inspired by the way brain neurons work. A perceptron is a mathematical model for an artificial neuron that receives various inputs, processes them using a weighted function, and decides on the output.

Rosenblatt’s hope was that one could feed a neural network a set of data, such as photographs of men and women, and the neural network, like humans, could learn how to separate the photographs; But there was one problem: the perceptron model didn’t work very well. Rosenblatt’s neural network was a single layer of neurons and was too limited to perform the assigned task of image separation.

Even when no one believed in artificial intelligence, Hinton didn’t lose hope

In the late 1960s, Rosenblatt’s colleague wrote a book about the limitations of Rosenblatt’s neural network. After that, for about ten years, research in the field of neural networks and artificial intelligence almost stopped. No one wanted to work in this field, because they were sure that no clear results would be obtained. Of course, nobody might not be the right word, and it is better to say almost nobody; Because the topic of artificial intelligence and neural network was completely different for Hinton.

Hinton believed that there must be a way to simulate the human brain and make a device similar to it. He had no doubt about it. Why did Hinton want to pursue a path that few would follow and almost no one saw a happy ending for? Thinking that everyone makes mistakes, this eminent scientist continued on his way and did not give up.

From America to Canada; A journey that changed the course of artificial intelligence

Hinton went to different research institutes in America during his research. At that time, the US Department of Defense funded many US research institutions, so most of the projects carried out or underway focused on military objectives. Hinton was not interested in working in the military field and was looking for pure scientific research and the development of technology for human and general applications. As a result, he was looking for a place where he could continue his research away from the pressures of the military and the limitations of dependent funds.

I did not want my research to be funded by military organizations, because the results obtained would certainly not be used for human benefit.

– Geoffrey Hinton

After searching for a suitable place to continue research, Canada seemed to be the most suitable option. Finally, Hinton moved to Canada in 1987 and began his research at the University of Toronto. In the same years, Hinton and his colleagues were able to solve problems that simpler neural networks could not solve by building more complex neural networks.

Hinton and his colleagues developed multilayer neural networks instead of building and expanding single-layer neural networks. These neural networks worked well and drew a null line on all disappointments and failures. In the late 80s, a person named Dean Pomerleau built a self-driving car using a neural network and drove it on different roads.

In the 1990s, Yann LeCun, one of the pioneers of artificial intelligence and deep learning, developed a system called “Convolutional Neural Networks” (CNNs). These networks became the basis for many modern techniques in machine vision and pattern recognition. One of the first important applications of these networks was to build a system that could recognize handwritten digits; But once again, after the construction of this system, researchers in the field of artificial intelligence reached a dead end.

In the 1990s, an interesting neural network was built, but it stalled due to insufficient data.

The neural networks built at that time did not work well due to the lack of sufficient data and the lack of necessary computing power. As a result, educated people in the fields of computer science and artificial intelligence once again concluded that neural networks and their construction were nothing more than a fantasy. In 1998, after 11 years at the University of Toronto, Geoffrey Hinton left Toronto to found and manage the Gatsby Computational Neuroscience Unit at University College London. During his research at this center, he studied neural networks and their applications.

AlexNet: A Milestone in the History of Artificial Intelligence

From the 1990s to 2000, Hinton was the only hopeful person on the planet who still believed in the development of neural networks and artificial intelligence. Hinton attended many conferences to achieve his goal but was usually met with indifference by the attendees and treated like an outcast. You might think to yourself that Hinton never gave up and moved on with hope, but that’s not the case. He was also sometimes disappointed and doubted reaching the desired result; But by overcoming despair, he continued his way no matter how difficult it was; Because this sentence kept repeating in Hinton’s mind: “Computers can learn.”